Ball Mill Services

Why Geoservex

Ball Mill Services

![]()

We are well experienced in various design of OEM makes ball mills in order to evaluate the condition of ball mill. An inspection to be executed by our Geoservex Mill specialists with in-depth knowledge of complete mill components for ensuring optimal, trouble-free operation.

Geoservex-India proudly launching “Ball Mill Mechanical Inspection” (BMI) services for all the esteemed customers.

Inspection during Static

Condition of the mill

![]()

To get a detailed picture of the mill’s overall condition, including parts that need to be replaced, it is important to carry out an external and internal inspection during standstill.

NDT Analysis

- Checking of thickness of trunion journal.

- Mill Shell Thickness.

- UT of trunion journal.

- UT of all welding joints.

- UT of all T Joints.

- MPI of Girth Gear and Pinion.

- MPI of Mill Manhole door.

- MPI of trunion neck area.

Inspection and measurement

- Mill trunion radial run out.

- Mill lifting at inlet/outlet.

- Mill slide ring radial run out.

- Measurement of Girth Gear axial and radial run-out.

- Measurement of root gap & backlash of gear and pinion.

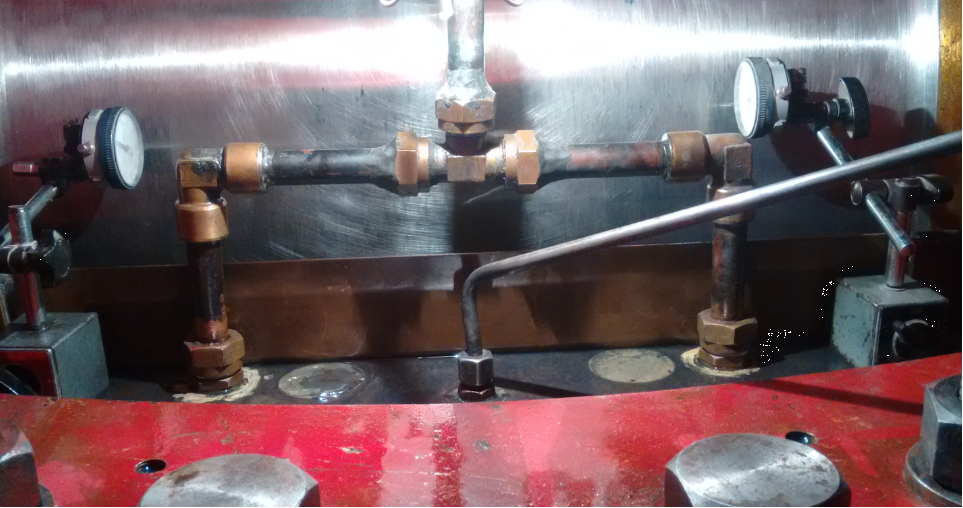

- Inspection of trunion lubrication unit.

- Visual inspection of mill components.

Key

Benefits

![]()

- Minimize the downtime.

- Optimize the mill availability.

- Performed during operation/standstill of mill.

- Uninterrupted production.

- Executed by highly experienced Geoservex mill specialist.

- Final presentation and sharing of knowledge with plant personnel.

- Recommendations for future improvements.

Final

Report

![]()

When inspections of mill components have been carried out, our specialists provide a final comprehensive technical evaluation and analysis report, as well as recommendations for repairs, spare parts, adjustments and optimizations.

The report is an essential document to help production and maintenance departments plan future maintenance activities, such as ensuring that the right spare parts are available, and – most importantly – avoid unscheduled, costly shutdowns.

The following information will be available in our detailed report for availability of mill in continuous operation without any breakdown.

- Action to be taken as soon possible.

- Action to be taken during shutdown.

- Action to be taken for future activities.

- Modification of mill maintenance.

- Spare parts managements.

Contact Us

Contact Us