Hot Kiln Alignment

Why Geoservex

Hot Kiln Alignment

![]()

In Geoservex for 40 years we have been dealing with rotary kiln alignment in the whole world. We are the pioneers of hot kiln alignment method and worldwide leader of this service in the global market.

We are specialized in preventive actions and do not offer components (we are not any product supplier & supports any OEM), which guarantees objective assessment of the machine state and give genuine results.

We consider the kiln inspection as a service improving the mechanical condition of the running kiln, and this is our only overriding goal.

Hot Kiln

Alignment during operation of Kiln

![]()

Kiln alignment has to be carried out during the normal operation of the kiln in order to obtain the most realistic information and data on the condition of the kiln without disturbing the clinker production.

As a part of a preventive maintenance, Kiln alignment identifies the actual cause behind problems and recommends a more appropriate solution. Our alignment approach is based on advanced measuring techniques and customized hardware and software. It is evaluated by experienced alignment specialists. Based on our experience and considering major root causes to all kiln failures, our alignment method aims to improves and ensures kiln availability by optimization of Kiln Axis, Kiln shell ovality, Kiln crank and Kiln axial balance. The detail scope of service as follows,

Kiln Axis

- Measurement of kiln axis position in horizontal and vertical plane by using advanced survey method.

- Measurement and calculation of tire and supporting rollers diameter by using electronic instrument.

- Measurement of base frame foundation settlement.

- Preparation of optimal version of support roller adjustment program and schedule.

Kiln Shell Ovality

- Kiln shell ovality test at all supports. (direct survey of elastic deformation of the kiln shell)

- Measurement of tire migration and calculation of under-tire clearance.

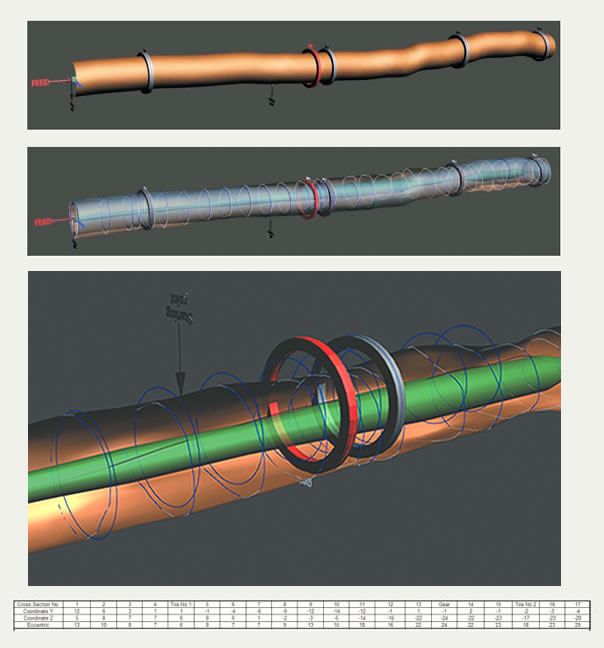

Kiln Crank

- Measurement of supporting rollers shaft cyclical deflection.

- Measurement of tires wobbling.

- Measurement of kiln shell profile at all shell sections.

- Measurement of kiln shell permanent deformations.

- Preparation of shell animation model. (unique full 3D rotating shell)

- Measurement of kiln shell temperatures distribution. (indication of shell temperature crank)

Kiln Axial Balance

- Measurement of supporting rollers axis position, rollers skewing and operating angle.

- Measurement of supporting rollers inclination and base frame axial slope.

- Measurement of supporting rollers profiles. (mechanical wear of running surface).

- Evaluation of kiln thrust and mechanical balance.

Supplementary Measurements

- Measurement of Girth gear wobbling.

- Measurement of thrust rollers position in reference to the kiln axis.

- Checking kiln drive alignment. *(option-the kiln must be stopped for a few hours due to safety reasons)

- General mechanical inspection of drive mesh, support roller bearings and shafts condition, lubrication efficiency, inlet and outlet sealing, thrust unit, adjustment equipment, covers and housing.

Comprehensive Kiln Inspection

Additional data are required from plant to do Engineering study of kiln. The following results has to be given by doing comprehensive kiln inspection.

- Current loads on piers.

- Pressure on bearings.

- Hertz pressures on roller-tire contact.

- Bending stress in the kiln shell.

- Stress in the tires.

- Stiffness matrix, optimization of kiln vertical axis position considering load distribution.

Preparation and submission of completed report including results of survey, short- and long-term recommendations for preventive maintenance actions.

Advantages

of doing Geoservex Method

![]()

- After completion of kiln axis correction, we do cross check of kiln axis measurement.

- Diameter measurement and calculation of tire and support roller by using electronic instrument.

- Surface wear profile measurement of support roller at 4-5 locations.

- Measurement of support roller axis position and roller skewing.

- Measurement of roller operating angle.

- Kiln shell animation model and submitting in pdf format. (unique full 3D rotating shell).

- Calculation of under tire clearance.

- Measurement of axial deviation on drive station. (Pinion to Gear box)

- Measurement of thrust roller position with respect to kiln axis.

- All the measured readings and its results are very high accuracy and manual error can be eliminated by using advanced survey instrument with software.

- Output data can be cross check and evaluated by calculations.

Benefits

of doing HKA once in 2 years

![]()

- Prevention against uneven load on supports.

- Higher equipment availability and longer kiln life.

- Elimination of excess longitudinal stress in the shell, no more cracks of shell.

- Elimination of high thrust forces for rollers, tires side guidance and thrust rollers.

- Elimination of hot bearings and hot thrust collars.

- Prevention against refractory loss and excess of ovality.

- Reduction of heavy torque for kiln drive coming from misalignment and unbalanced opposite thrust forces.

Final

Report

![]()

When Hot Kiln Alignment have been carried out, our specialists provide a final comprehensive technical evaluation and analysis report, as well as recommendations for adjustments, repairs, spare parts, and optimizations.

The report is an essential document to help production and maintenance departments plan future maintenance activities, such as ensuring that the right spare parts are available, and – most importantly – avoid unscheduled, costly shutdowns.

The following information will be available in our detailed report for high availability of kiln

- Action to be taken as soon possible.

- Action to be taken during next kiln shutdown.

- Action to be taken for future activities.

Contact Us

Contact Us