About us

Few High lights of

Geoservex India

![]()

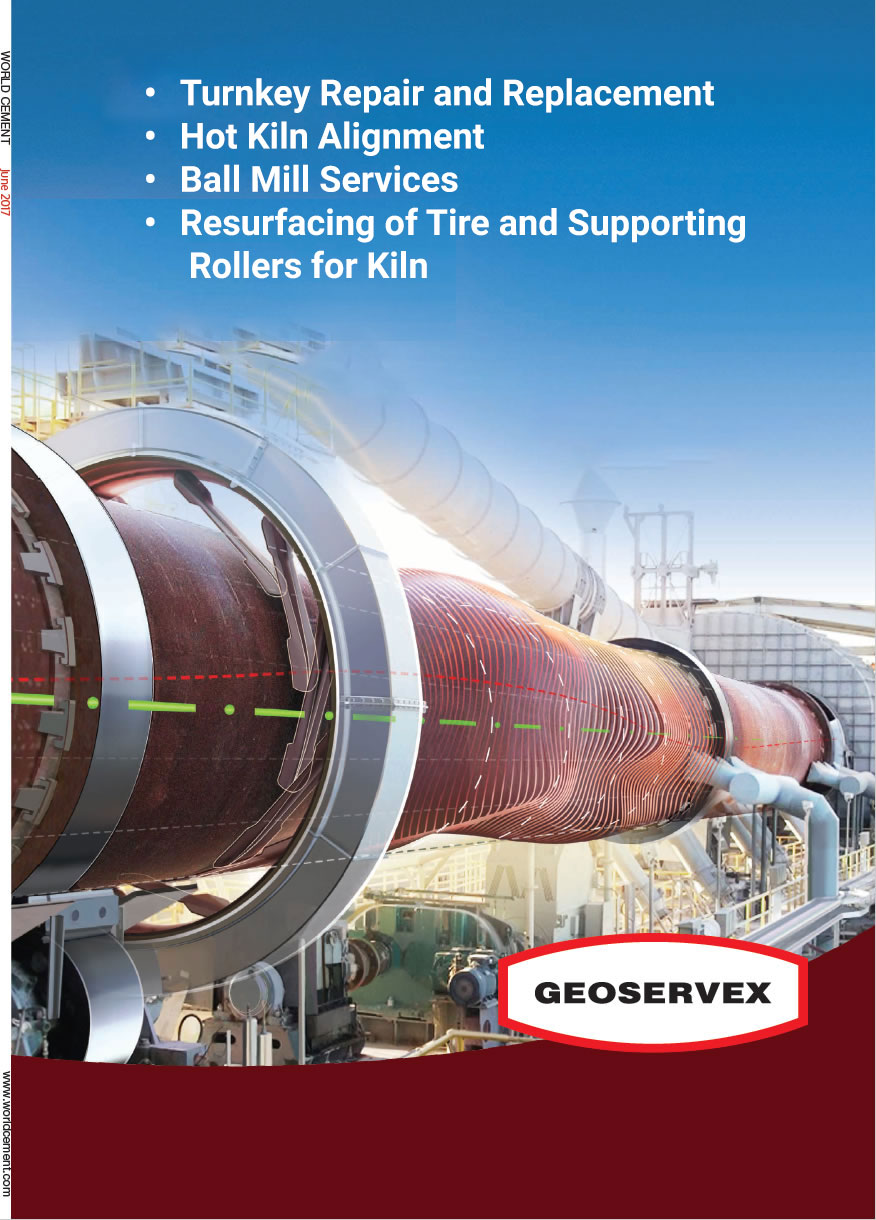

We Geoservex-India is a company having its headquarters in Chennai, India and our global headquarters at Poland. We are employee owned, customer focused, quality driven organization expert in Plant maintenance services of key rotary equipment in cement, steel or fertilizer plant such as kilns, dryer, granulator and ball mills.

Our sole aim is to provide best possible services in the industry to all the esteemed customers. Globally Geoservex has been dealing with kilns since 40 years and are the market leaders in hot kiln alignment. We are now moving one step further by providing end to end solutions in kiln such as in-situ grinding, supervision and turnkey & replacement. We are well placed with very experienced specialists and extensive support of our associates in turnkey jobs.

We are also extending our support in ball mills. With very experienced mill specialists in our team, we can do ball mill inspection and repair & replacement of ball mill components on turnkey or supervision services.

We are Pro-active on safety. In Turnkey repair and replacement services, we depute qualified safety supervisor along with our specialist to ensure round the clock safe act + method + behavior. Our team work nurtures safe work environment for our employees and sub-contractor’s workmen the same we ensure to strictly follow. We stand committed to continue doing our best by making safety a mandatory requirement for all our employees and sub-contractors workmen. Please note all our tools are certified by recognized agency and we provide mandatory safety training to all our engineers.”

We are service based company and do not offer components (we are not product supplier & do not support any OEM). This guarantees objective assessment of the machine and give genuine results. We consider the inspection of equipment as a service to improving the mechanical condition of the equipment and this is our only overriding goal.

Benefits Coming

From Geoservex Hot Kiln Alignment

![]()

1. Prevention Against Uneven Load Of Supports

2. Elimination Of Excess Longitudinal Stress In The Shell, No More Cracks Of Shell

3. Elimination Of High Thrust Forces For Rollers, Tires And Side Guidance And Thrust Rollers

4. Elimination Of Hot Bearings And Hot Thrust Collars

5. Prevention Against Refractory Loss And Excess Of Ovality

6. Reduction Of Heavy Torque For Kiln Drive Coming From Misalignment And Unbalanced Opposite Thrust Forces

7. Reduction Of Energy Consumption

Benefits Coming

From Geoservex Kiln Inspection

![]()

Contact Us

Contact Us