Resurfacing of tire and supporting rollers

Why Geoservex

Resurfacing Of tire And Supporting Rollers

![]()

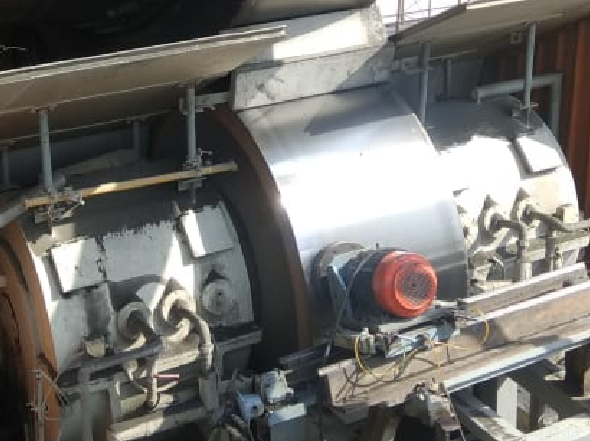

Geoservex-India proudly launching “Resurfacing of tire and Supporting Rollers” (RTAR) services for all the esteemed customers. We have specifically designed machines to accommodate and suitable for various OEM makes rotary kiln/dryer and different dimensions of tire and rollers. All work is completed by experienced Geoservex Grinding specialist.

Why

Resurfacing (RTAR)

![]()

Rotary kilns, dryers and similar types of rotary equipment stay in continual operation most of the year and as time goes by, various types of wear problems occur. RTAR and roller naturally form irregular surface profiles due to improper skewing of rollers and in addition to pitting due to raw dust, spalling, irregular markings and rolled-over edges.

Maintain and Improve the Mechanical Stability of Rotary Kiln/Dryers

![]()

Consequences if Not Performing RTAR

- Vibrations at the supports

- Inability to control axial balancing of kiln, misalignment

- Premature bearing failure

- Increased main drive power consumption

- Damage to tyre retaining components, and

- Damage to support bases, and drive components.

Geoservex RTAR Services

Geoservex kiln specialist can control the behavior of the kiln/rotary equipment during the Resurfacing process:

- Resurfacing removes work hardening and minimize the damage of the fresh surfaces.

- Resurfacing of tire thrust face and thrust roller, to remove the waviness over the thrust face and also to remove the flat marks, step over the thrust roller top and bottom land and tire thrust face while kiln in operation.

- Resurfacing changes the thrust characteristics of the support rollers and allow free travel of the roller in the support bearings.

- These changes are continuously monitored during the process and adjustments are made to control the position of the kiln/rotary equipment.

- Geoservex specialist accurately measure and report the diameter before and after the resurfacing and necessary support rollers adjustment has to be carryout without disturbing the kiln production.

Benefits by doing

Resurfacing of tire and supporting rollers

![]()

- Reduce the power consumption of drive station.

- Improves the mechanical stability of kiln/dryer.

- Improve the contact between tire and rollers.

- Eliminate vibration at the supports.

- Requires zero downtime.

- Support roller adjustment for skew correction.

- Improves the axial balancing of kiln.

- Plant operation is uninterrupted.

- Minimize the operating cost.

- Prolong service life.

Sample Works

![]()

Condition of Supporting Roller Grinding

Condition of tire Before

Grinding

Grinding

Contact Us

Contact Us